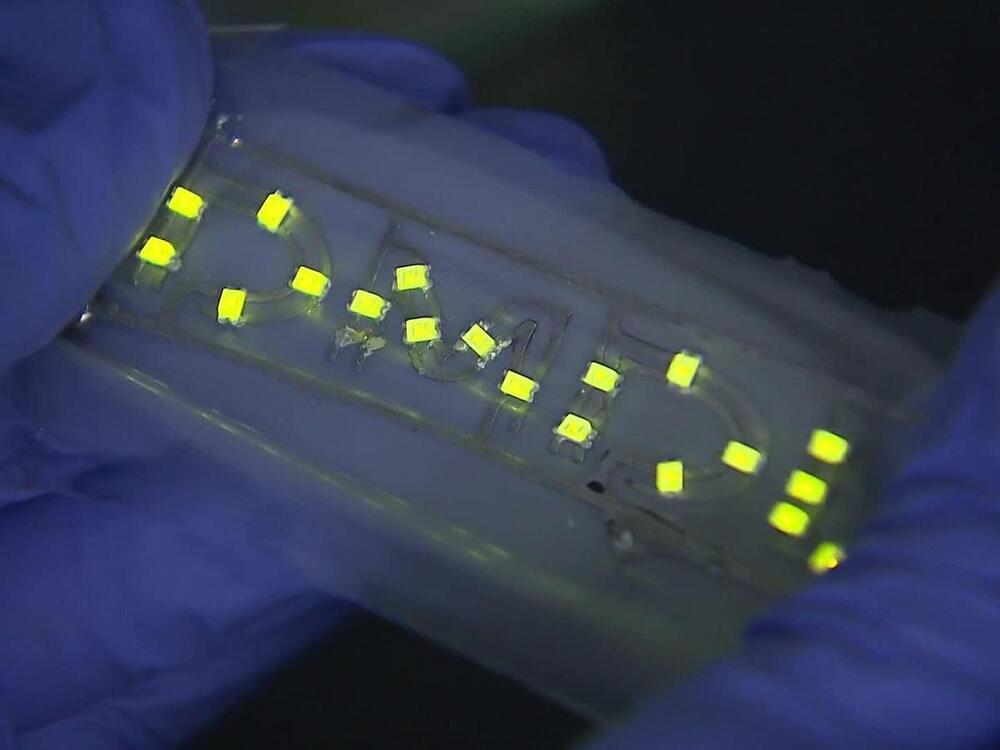

A team in Korea has used sound waves to connect tiny droplets of liquid metals inside a polymer casing. The novel technique is a way to make tough, highly conductive circuits that can be flexed and stretched to five times their original size.

Making stretchable electronics for skin-based sensors and implantable medical devices requires materials that can conduct electricity like metals but deform like rubber. Conventional metals don’t cut it for this use. To make elastic conductors, researchers have looked at conductive polymers and composites of metals and polymers. But these materials lose their conductivity after being stretched and released a few times.

Liquid metals, alloys that stay liquid at room temperature, are a more promising option. Gallium-based liquid metals, typically alloys of gallium and indium, have caught the most attention because of their low toxicity and high electrical and heat conductivity. They are also tough because of an oxide skin that forms on their surface, and they stick well to various substrates.

Leave a reply